- High strength nylon wear-resistant bucket, the lifting capacity of> 15 tons per hour is larger;

- 1156mm large drying, section design, balance air volume, reduce resistance, effectively improve the utilization rate ofhot air and drying rate

- The drying, section is made ofstainless steel wear-resistant material with long service life.

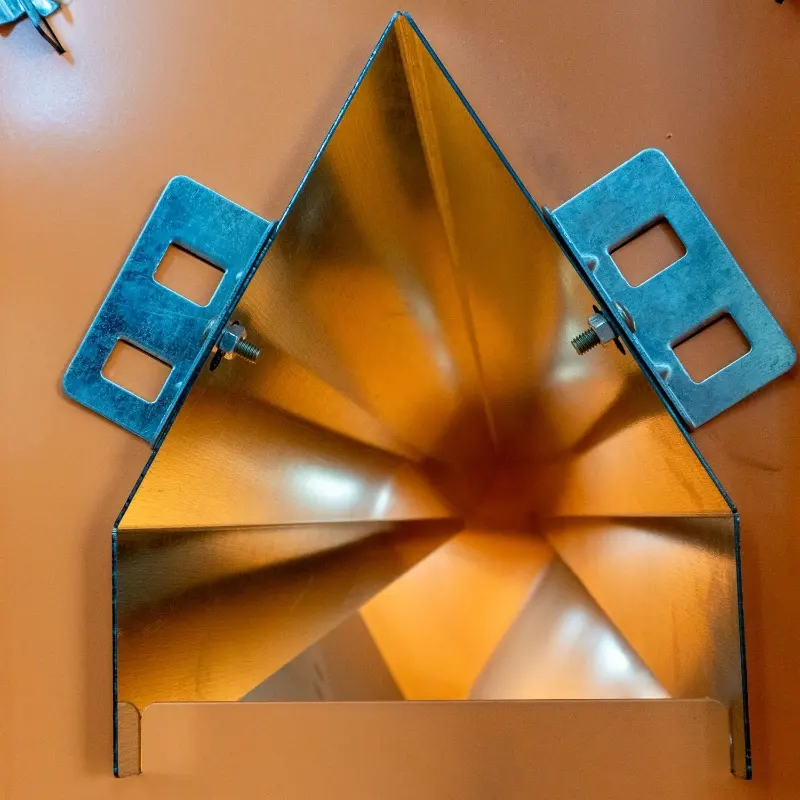

- Exclusive standard fireproofequipment, to ensure safety more peace of mind;

- Personalized programmable control system, optional with remote operation and maintenance, diagnosis, weighing system, more intelligent;

- The classic conveying method, the grain circulation process is more uniform and smooth, and the drying is more uniform (drying non-uniformity< 19).

Drying Machines 12 tons horizontal flow with auger up and down

- 12ton cross type(auger)

Features

Product Introduction

Parameter

Product Categories

How Can We Help You

Feel free to contact us. We are available 24/7 via email or phone.

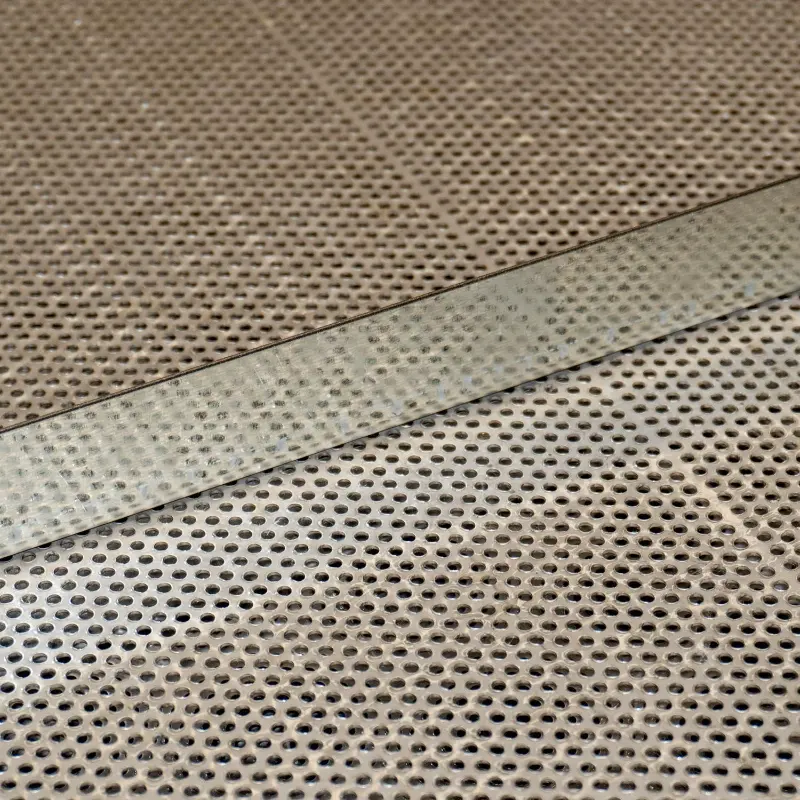

The drying layer mesh plate of the cross flow dryer is made of high-quality stainless steel material, which has strong corrosion resistance, longer service life, and better temperature transfer effect; The mesh adopts 2.5-3.0mm to ensure even passage of grains and more uniform heating.

The dustbin made of thick PP material is designed to be more wear-resistant, and the conveyor belt is also thickened to improve its stability, durability, and reduce customer costs in the later stage

The main engine chassis is simple and easy to clean by using gravity bearing calculation.

The hoist adopts new structure design to guide grain and reduces 80% damage.

The lower winch of the main engine adopts the connecting rod structure design, and the grain discharge rate reaches 98%.

Cancel the structure of hanging dragon and reduce physical fragmentation.

Using Siemens Electrical Appliances:

1. A globally renowned brand with high stability and guaranteed quality, reducing equipment failures

2. High reliability, with a global supply chain, convenient for maintenance and replacement

3. High quality, longer service life, and higher accuracy

The whole body is made of manganese steel material, which is wear-resistant and durable. The part in contact with grains is made of 201 stainless steel material, which prolongs the service life of the equipment

|

Model |

12ton cross type(auger) |

||

|

Structure type |

Batch type circulating |

||

|

Drying way |

Indirect heating |

||

|

Drying type |

Cross flow |

||

|

Dimension(L*W*H)mm |

3160*3960*9040 |

||

|

Batch volume(t/d) |

12 |

||

|

Moisture(%/h) |

0.5-1.2 |

||

|

Height of drying layer(mm) |

1156 |

||

|

Height of the tempering layer(mm) |

5570 |

||

|

Effective volume(m³) |

22.8 |

||

|

Hot air temperature range(℃) |

40-90 |

||

|

Number of fan |

1 |

||

|

Total power of fan(kw) |

9(not include dust install) |

||

|

Productivity(t/h) |

≥15 |

||

|

Device |

Safety device |

Full grain alarm device, thermal relay, temperature controller, grain temperature sensor, hot air temperature sensor, overload protection, leakage protection device. |

|

|

|

Standard device |

Online moisture meter, online temperature detector, dryer base, dryer discharging layer, drying layer, tempering layer, elevator, hot air blower, guard railing, ladders, etc. |

|